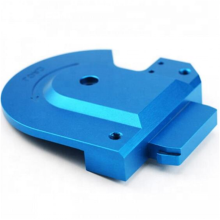

Customized Machining Of Turned Aluminum Parts

Unit Price: USD 1000 - 200 / Set/Sets

| Min.Order |

Unit Price |

| 1 Set/Sets |

USD 1000 / Set/Sets |

| 1 Set/Sets |

USD 200 / Set/Sets |

place of origin: China

Forming method: Plastic Injection Mould

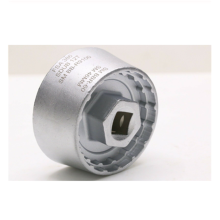

product material: Rubber, Metal, Plastic, Steel, Aluminium, Copper

product: Vehicle Mould, Household Appliance, Household Product

Mould Base: Lkm, Dme, Hasco Etc

Mold Cavity And Core Steel: P20, 718h, Nak80, H13, S316h, 1.2083,1.2085, 1.231

Plastic Material: Pp,Ps,Abs,As,Pvc,Pa+Gf,Pbt,Pc,Pc/Abs,Pe,Hdpe,Pmma

Runner: Cold/Hot,Moldmaster,Yudo,Heitec,Gunther,Synventive

Standard Parts: Dme, Hasco, Ect.

Mold Steel Tolerance: +/-0.01mm

Mold Life: 1,500,000 Shots

Free Service: Free Process Improvement And Mould Design

Product Tolerance: +/-0.02mm

One-stop Service: Design,Prototype,Mold,Injection Molding,Package

Packaging: Wooden box for molds, carton for products

Brand: OEM

Transportation: Ocean,Land,Air,s

Supply Ability: 20 sets moulds, 2 millions pcs products

Port: SHENZHEN,GUANGZHOU

Customized Machining Of Turned Aluminum Parts Reasonable selection of cutting amount for CNC lathe processing: For high-efficiency metal cutting processing, the material to be processed, the cutting object, and the cutting conditions are three basic elements. These determine machining time, tool life and machining quality. An economical and useful machining method is bound to be a reasonable selection of cutting conditions. The three elements of cutting conditions: cutting rate, feed and...

Product Categories : Aluminum Molding

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )

Contact Now

Contact Now

Contact Now

Contact Now