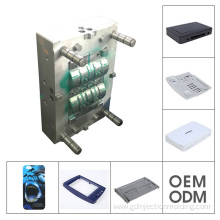

Processing And Customization Of Plastic Molds

Unit Price: 0.01~10USD

Payment Type: T/T,Others

Terms of Trade: FOB,CIF,EXW,DDP

Min. Order: 100

Unit Price: USD

Model No.:other plastic parts

Plastic molding process type: Injection

Processing Service: Moulding

Mould Base: Lkm, Dme, Hasco Etc

Mold Cavity And Core Steel: P20, 718h, Nak80, H13, S316h, 1.2083,1.2085, 1.231

Plastic Material: Pp,Ps,Abs,As,Pvc,Pa+Gf,Pbt,Pc,Pc/Abs,Pe,Hdpe,Pmma

Runner: Cold/Hot,Moldmaster,Yudo,Heitec,Gunther,Synventive

Standard Parts: Dme, Hasco, Ect.

Mold Steel Tolerance: +/-0.01mm

Mold Life: 1,500,000 Shots

Free Service: Free Process Improvement And Mould Design

Product Tolerance: +/-0.02mm

One-stop Service: Design,Prototype,Mold,Injection Molding,Package

place of origin: China

Packaging: Wooden box for molds, carton for products

Productivity: 10000000000

Brand: OEM

Transportation: Ocean,Land,Air,s

Place of Origin: china

Supply Ability: 20 sets moulds, 2 millions pcs products

Port: SHENZHEN,GUANGZHOU

Processing And Customization Of Plastic Molds There are two main purposes of polishing the mold: one is to increase the brightness and beauty of the Plastic Mold ; the other is to make the mold easy to demould.When polishing, generally use a coarse oilstone to roughen the surface of the machined mold cavity, grind to remove the knife marks of the machined tool, and then use a fine oilstone to polish the rough oilstone to achieve the traces, and then use a fine The surface polished by...

Product Categories : Injection Molding Service > other plastic parts

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )

Contact Now

Contact Now

Contact Now

Contact Now