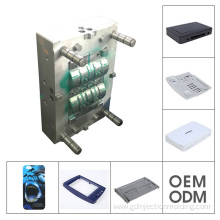

Injection Mold Processing Parts Processing

Unit Price: 0.01~10USD

Payment Type: T/T,Others

Terms of Trade: FOB,CIF,EXW,DDP

Min. Order: 100

Unit Price: USD

Model No.:other plastic parts

Plastic molding process type: Injection

Processing Service: Moulding

Mould Base: Lkm, Dme, Hasco Etc

Mold Cavity And Core Steel: P20, 718h, Nak80, H13, S316h, 1.2083,1.2085, 1.231

Plastic Material: Pp,Ps,Abs,As,Pvc,Pa+Gf,Pbt,Pc,Pc/Abs,Pe,Hdpe,Pmma

Runner: Cold/Hot,Moldmaster,Yudo,Heitec,Gunther,Synventive

Standard Parts: Dme, Hasco, Ect.

Mold Steel Tolerance: +/-0.01mm

Mold Life: 1,500,000 Shots

Free Service: Free Process Improvement And Mould Design

Product Tolerance: +/-0.02mm

One-stop Service: Design,Prototype,Mold,Injection Molding,Package

place of origin: China

Packaging: Wooden box for molds, carton for products

Productivity: 10000000000

Brand: OEM

Transportation: Ocean,Land,Air,s

Place of Origin: china

Supply Ability: 20 sets moulds, 2 millions pcs products

Port: SHENZHEN,GUANGZHOU

Injection Mold Processing Parts Processing The speed and pressure of the fast mold opening can be appropriately increased to reduce the mold opening time of the plastic shell, but the distance between the fast mold opening position and the slow mold opening position must be properly opened, because the impact and inertia of the fast mold opening are relatively high. If it is large, a certain distance must be taken...

Product Categories : Injection Molding Service > other plastic parts

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )

Contact Now

Contact Now

Contact Now

Contact Now