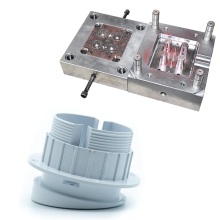

Plastic Mold Injection Processing Parts Processing

Unit Price: 0.01~10USD

Payment Type: T/T,Others

Terms of Trade: FOB,CIF,EXW,DDP

Min. Order: 100

Unit Price: USD

Model No.:other plastic parts

Plastic molding process type: Injection

Processing Service: Moulding

Mould Base: Lkm, Dme, Hasco Etc

Mold Cavity And Core Steel: P20, 718h, Nak80, H13, S316h, 1.2083,1.2085, 1.231

Plastic Material: Pp,Ps,Abs,As,Pvc,Pa+Gf,Pbt,Pc,Pc/Abs,Pe,Hdpe,Pmma

Runner: Cold/Hot,Moldmaster,Yudo,Heitec,Gunther,Synventive

Standard Parts: Dme, Hasco, Ect.

Mold Steel Tolerance: +/-0.01mm

Mold Life: 1,500,000 Shots

Free Service: Free Process Improvement And Mould Design

Product Tolerance: +/-0.02mm

One-stop Service: Design,Prototype,Mold,Injection Molding,Package

Packaging: Wooden box for molds, carton for products

Productivity: 10000000000

Brand: OEM

Transportation: Ocean,Land,Air,s

Place of Origin: china

Supply Ability: 20 sets moulds, 2 millions pcs products

Port: SHENZHEN,GUANGZHOU

Plastic Injection Molding Manufacturer When a Plastic Mold is injection molded, shrinkage in thick parts of the plastic mold structure (such as ribs or protrusions) is more severe than in adjacent parts because the cooling rate in thick parts is much slower than in thin parts . Different cooling rates can create dents on the joint surface, also known as shrink marks. This defect jeopardizes the...

Product Categories : Injection Molding Service > other plastic parts

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )

Contact Now

Contact Now

Contact Now

Contact Now