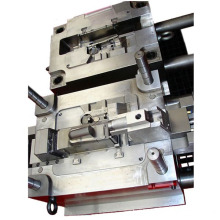

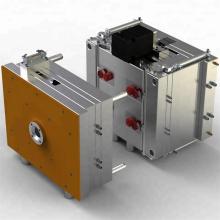

Parts Injection Molding Rapid Prototyping

Unit Price: USD 100000 - 500 / Set/Sets

| Min.Order |

Unit Price |

| 1 Set/Sets |

USD 100000 / Set/Sets |

| 1 Set/Sets |

USD 500 / Set/Sets |

Model No.:Plastic Mold

place of origin: China

Forming method: Plastic Injection Mould

product material: Rubber, Metal, Plastic, Steel, Aluminium, Copper

product: Vehicle Mould, Household Appliance, Household Product

Mould Base: Lkm, Dme, Hasco Etc

Mold Cavity And Core Steel: P20, 718h, Nak80, H13, S316h, 1.2083,1.2085, 1.231

Standard Parts: Dme, Hasco, Ect.

Mold Steel Tolerance: +/-0.01mm

Mold Life: 1,500,000 Shots

Free Service: Free Process Improvement And Mould Design

Product Tolerance: +/-0.02mm

One-stop Service: Design,Prototype,Mold,Injection Molding,Package

Plastic Material: Pp,Ps,Abs,As,Pvc,Pa+Gf,Pbt,Pc,Pc/Abs,Pe,Hdpe,Pmma

Runner: Cold/Hot,Moldmaster,Yudo,Heitec,Gunther,Synventive

Packaging: Wooden box for molds, carton for products

Brand: OEM

Transportation: Ocean,Land,Air,s

Place of Origin: CHINA

Supply Ability: 20 sets moulds, 2 millions pcs products

Port: SHENZHEN,GUANGZHOU

Parts Injection Molding Rapid Prototyping In addition to polymers, various plastic additives (such as stabilizers, plasticizers, colorants, lubricants, reinforcing agents and fillers) are generally added to the raw materials used in Blow Molding to improve the molding process and product quality. Use performance or reduce the cost of the product. Additives and polymers are mixed and uniformly dispersed into powder, also known as dry mix. Sometimes the powder also needs to be processed into...

Product Categories : Plastic Mold

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )

Contact Now

Contact Now

Contact Now

Contact Now